Our Strength Optimization

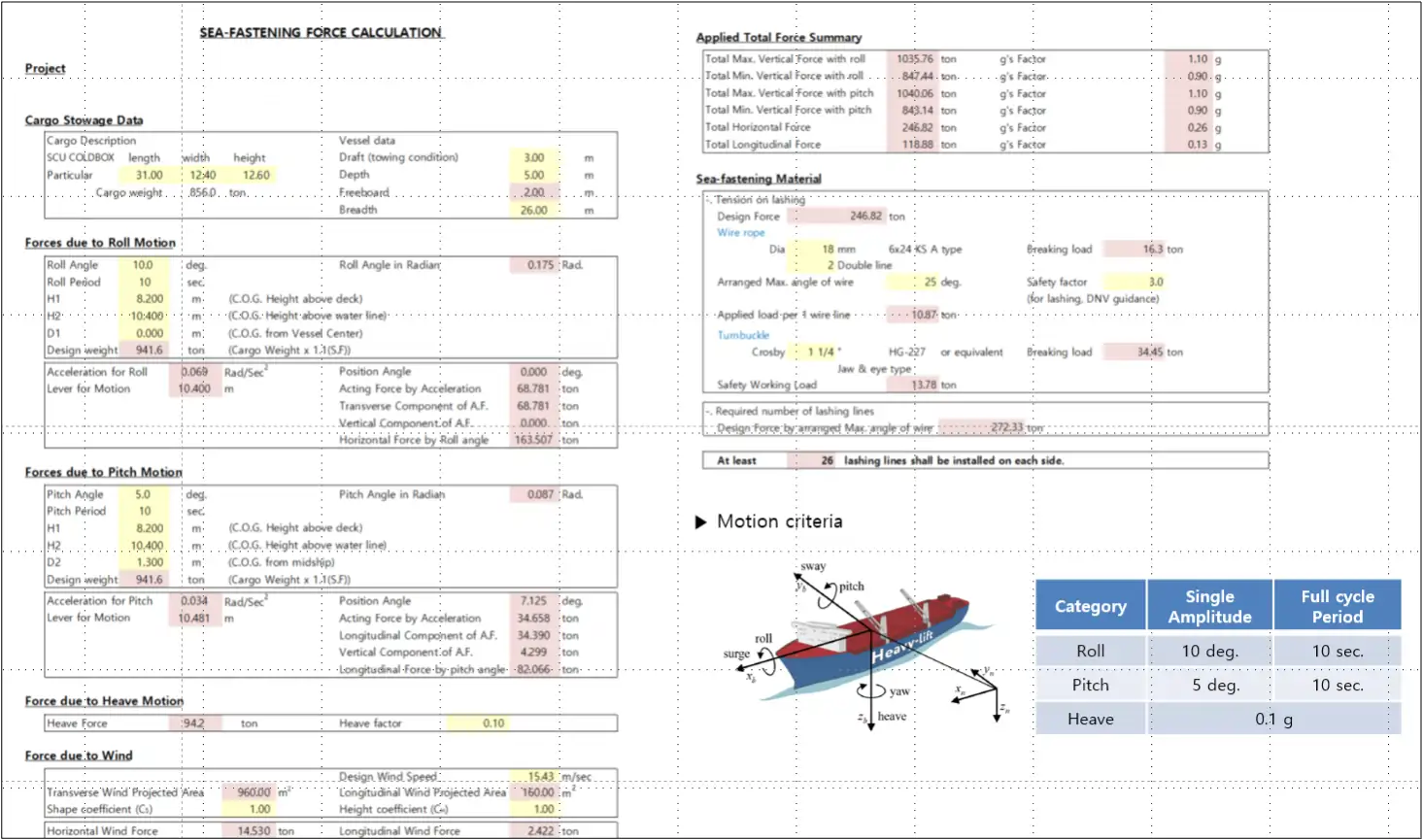

We do our own Container Load Plan for cost save and efficiency, which leads to overall cost reduction. We understand basic engineering for Lifting plan, Stowage Calculation, Roll/Pitch/Yaw Impact and provide best advice & solutions to our client.

Optimize Container Loading Plan

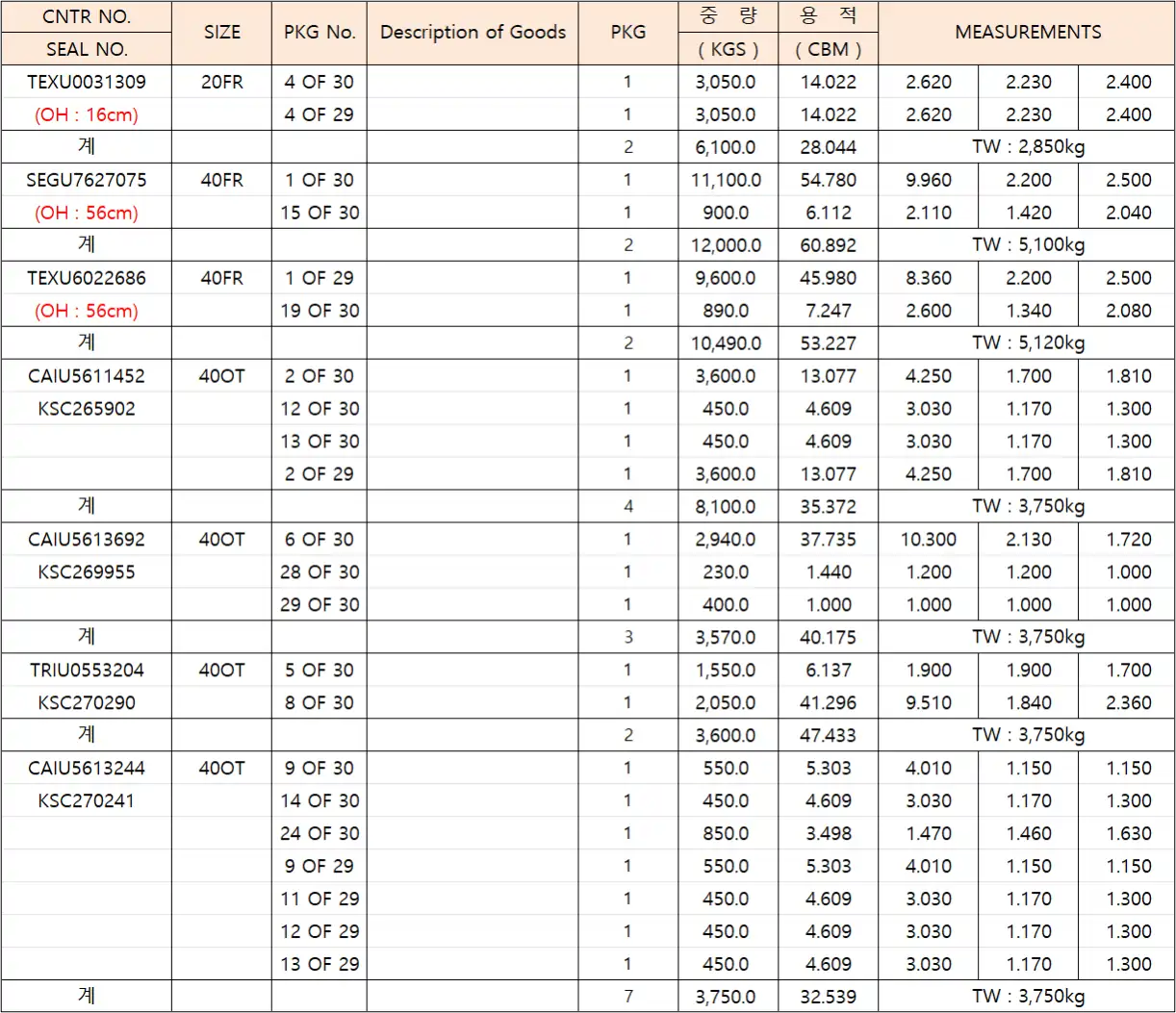

1. Analyze Cargo

- Cargo Dimension, Type, Volume Weight

- Center of Gravity

- Loading Balance

- Stackable

2. Select Container type

3. Space Utilization

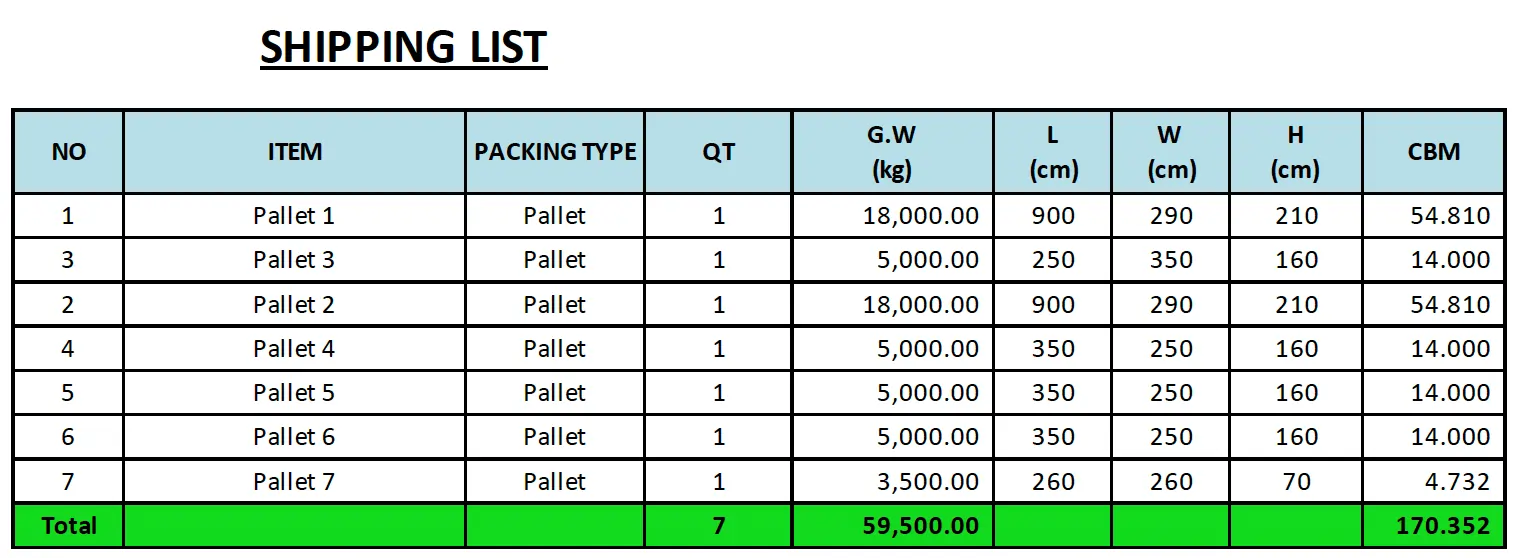

Container Loading Plan Example

Container Loading Plan Example

Original: Total 4 CNTR (40’FR(OWH)x2, 40’FR(OW)x1, 20’FR(OW)x1)

Optimized: Total 3 CNTR (40’FR(OWH)x2, 40’FR(OW)x1)

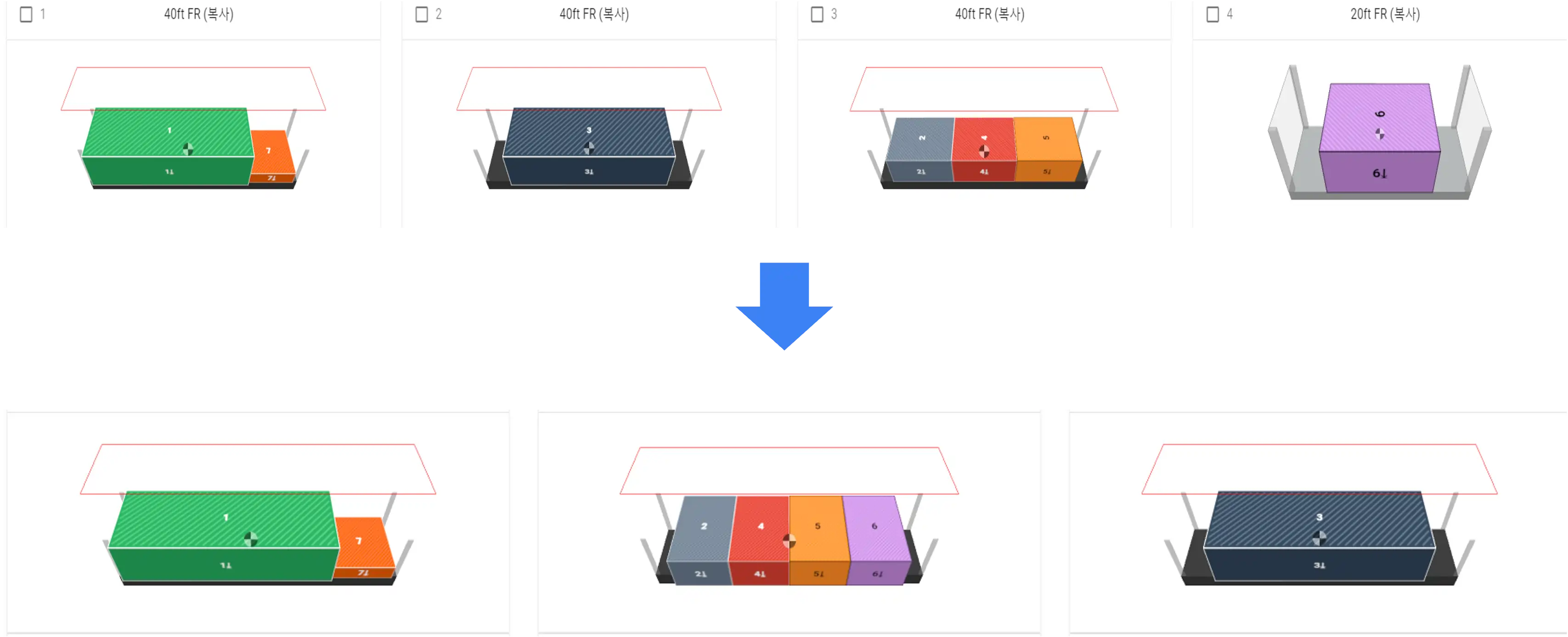

Lifting Plan Example

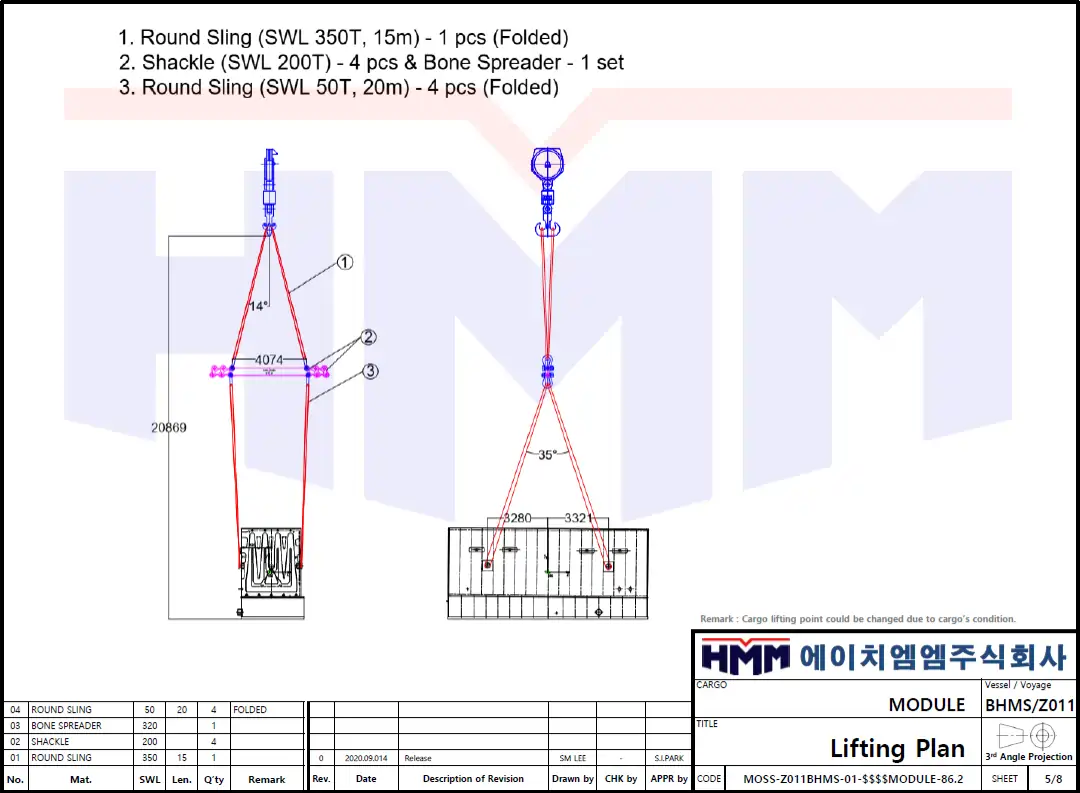

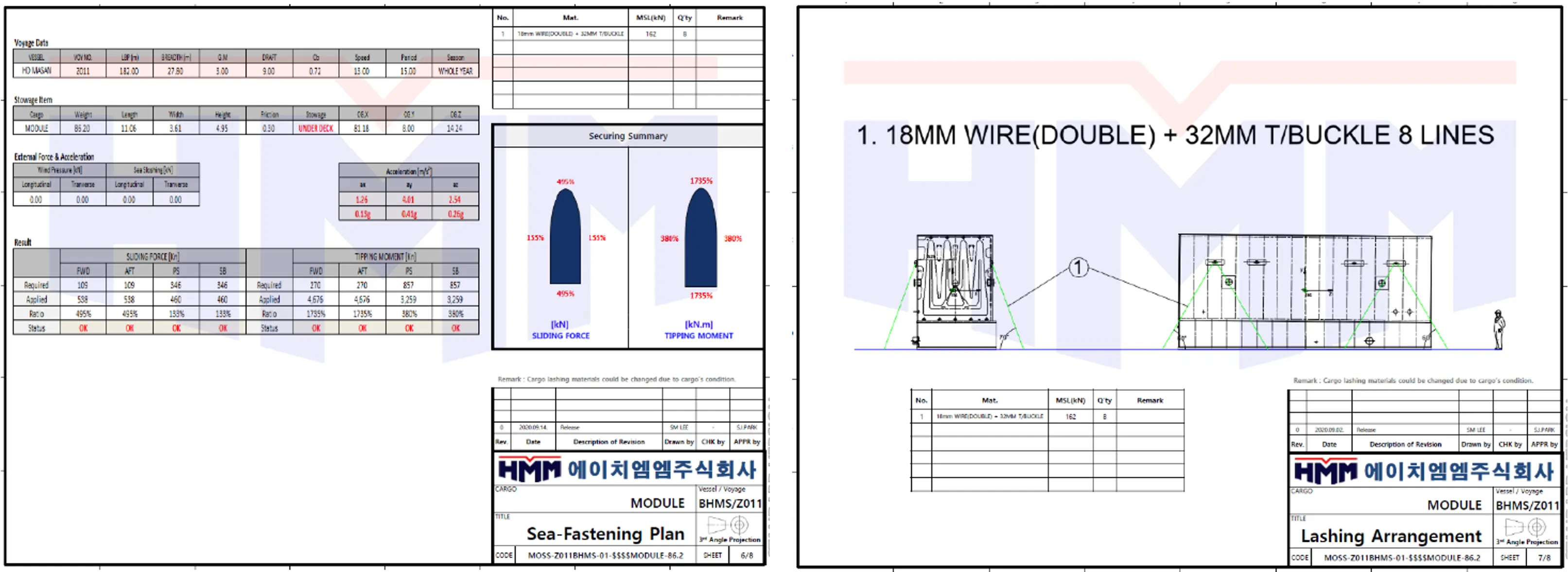

Sea-Fastening / Securing Plan Example

Force-Calculation Example

Network

We have a list of competitive sub-suppliers for the right service who we have been partners for a trustworthy period.

Your Trusted Partner in Global Logistics Innovation

From project cargo to regular transport, our industry-leading team and digital logistics solutions empower your business to stay ahead. Start your seamless global logistics journey today.